This case study was provided by the Construction Sector Accord. To read more about the Accord and view further case studies, click here.

Naylor Love reduces operational costs by diverting over 90% of its construction waste away from landfill.

Summary

Over the 19 years that she has been at Naylor Love, Annie Day has seen first-hand the negative impact that construction can have on the environment. It is estimated that construction and demolition waste make up to 50 percent of New Zealand’s total waste going to landfill 1. As one of Naylor Love’s environment managers, Annie was passionate about making a real difference and wanted to reduce the amount of waste the company was sending to landfill.

In collaboration with Auckland Council and others, Naylor Love carried out a waste trial at its construction site on Auckland University of Technology’ (AUT) North Campus. The trial involved separation of resources on site and making changes to how Naylor Love used and disposed of its leftover building products and materials. At the end of the trial period, over 90 percent of Naylor Love’s construction waste had been diverted away from landfill. This new approach allowed the company to make a saving of 40 percent on their usual landfill costs.

Naylor Love’s pilot project is an excellent example of the Accord’s fifth mid-term goal – Reduced waste and embodied and operational carbon. New Zealand has made some strong environmental commitments to reduce waste and carbon emissions, and the construction sector will need to play its part. Naylor Love’s work shows how diverting resources from landfill can reap benefits for both businesses and the environment. This case study showcases a number of ideas and practices that have kept common building products and materials out of the landfill.

Background

Construction waste is a growing environmental problem in New Zealand. Increasing construction activity generates significant waste and strains our landfills and waste management systems; it’s estimated that construction and demolition waste makes up to 50 percent of New Zealand’s total waste going to landfill. Waste is inextricably linked to resource loss, environmental pollution, and carbon emissions. It also imposes an economic burden on both construction businesses and consumers, as building products and materials are often bought and thrown away unnecessarily.

To address these issues, New Zealand’s construction sector needs to adopt environmentally sustainable practices, such as reducing construction waste and increasing the reuse and recycling of building products and materials. These practices are integral to what’s known as the circular economy. The circular economy is an economic system that maximises the value and use of resources by keeping them in circulation for as long as possible. Under a circular economy, resources are recovered and regenerated at the end of their useful life. It is an alternative to the traditional linear economy where resources are abandoned at the end of their use and become waste or pollution (often referred to as the ‘take-make-dispose’ approach).

Like many other construction businesses, Naylor Love initially had no road map for how its business could adopt more environmentally sustainable practices. However, attitudes within the company’s leadership team towards environmental issues started shifting over recent years, especially as new tools and technologies became more readily available. Annie used this momentum to help kickstart the company’s sustainability journey and explore whether Naylor Love could implement a circular economy approach to its work.

Annie started by upskilling herself and completed training courses with Otago Polytechnic Sustainable Practice Level 5, as well as Green Star and Homestar training courses with the New Zealand Green Building Council. This training helped Naylor Love form its sustainability strategy and the steps the company would need to take to become more sustainable. Building materials and waste management were two areas that the company decided it needed to focus on to reduce its environmental impact.

- Sustainable Business Network training(external link) - sustainable.org.nz

- New Zealand Green Building Council training(external link) - nzgbc.org.nz

- Naylor Love’s Sustainability Strategy(external link) - naylorlove.co.nz

Naylor Love case study video

Approach

When Naylor Love signed the contract to deliver three buildings at AUT’s North Campus, it was a great opportunity to put its sustainability strategy into action. Under the contract, Naylor Love agreed to divert 90 percent of its construction waste by weight from landfill.

Naylor Love realised the project presented an opportunity to collaborate with Auckland Council. It applied to Auckland Council’s Waste Minimisation and Innovation Fund and was awarded $35,000. Naylor Love and Auckland Council jointly set a number of goals for the waste trial and Mark Roberts, a Senior Waste Planning Specialist at Auckland Council, was a key partner who was present at the AUT North Campus worksite daily.

- Auckland Council’s Waste Minimisation and Innovation Fund(external link) - aucklandcouncil.govt.nz

“Construction and demolition is continuing to be the leading source of waste. There are conveniently held beliefs that you can’t do onsite sorting or that it’s not worth the effort. The work done on this project by the team at Naylor Love on the AUT site genuinely proves this is not the case.

Setting up systems, researching destinations for scrap materials, training staff and contractors and working with suppliers to reduce waste really pays off for an industry that is determined to improve productivity. Naylor Love are proving it.” Mark Roberts, Senior Waste Planning Specialist.

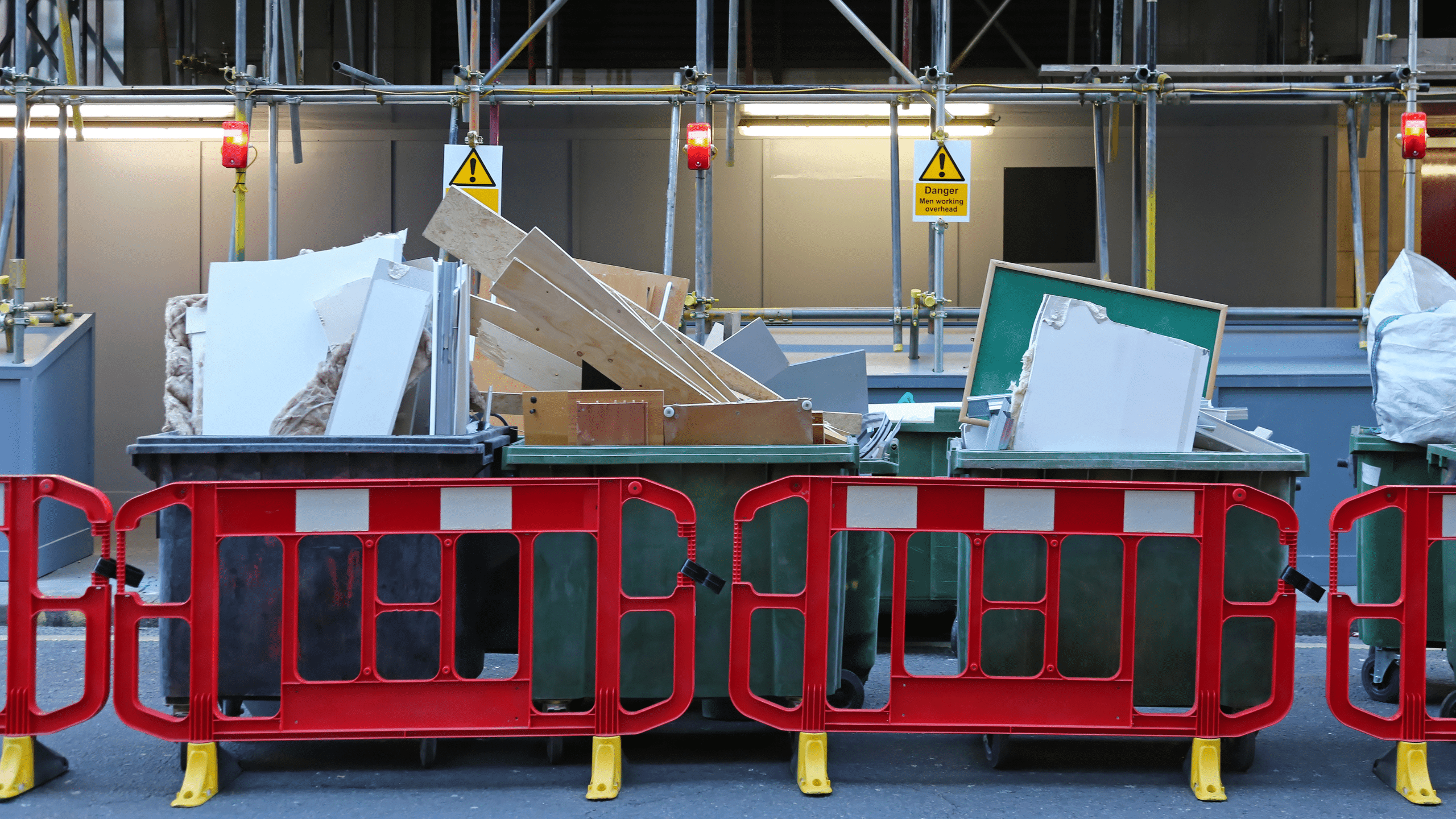

The initial steps that Naylor Love took were simple. They first created an accessible sorting area at the worksite where materials could be separated. They then provided different bins for different materials and put up clear signage so people would know which bins to use. The signs were made to be consistent with WasteMINZ guidelines.

- WasteMINZ(external link) - wasteminz.org.nz

Naylor Love quickly realised they needed to train people up to ensure they had the skillset to sort through, separate and distribute the right materials into the right bins. To ensure consistency of training within their own company, Naylor Love developed a NZQA micro-credential for Resource Sorters. Part of this qualification is now included in inductions on all Naylor Love worksites. Naylor Love has engaged an independent facilitator who delivers this course nationwide. Sub-contractors working on site are also trained in resource sorting, to ensure that everybody on site is doing the right thing, even when the Resource Sorters aren’t at the sorting area. Recognising that the rest of the construction sector could benefit from this tool, Naylor Love has made the qualification available to the rest of the industry.

- Resource Sorter and Safety Guide Video(external link) - youtube.com

- Resource Sorter Qualification(external link) - naylorlove.co.nz

Naylor Love examined the building products and materials they were using and saw that there were multiple actions they could take to divert resources away from landfill. They found that some products and materials could be easily sorted on site whilst others couldn’t. They also saw an opportunity to work much more closely with their suppliers to reduce, reuse and recycle their products and materials to divert them from landfill.

Changes to handling product and material waste

Naylor Love made the following changes to the way they handled specific product and material waste.

Cable ties

Cable ties are a ubiquitous presence on most worksites. Traditional cable ties are made from nylon and are non-recyclable. Naylor Love estimated they would that they would need approximately 8000 cable ties on two of the buildings on the AUT North Campus. After searching online, Annie found and imported a cable tie that was able to be unclipped and reused. The reusable cable ties have been working well on the AUT North Campus worksite and Naylor Love is now using them on another worksite for attaching temporary scrim to fencing and the climbing formwork. Naylor Love is currently working with engineers at Beca and others in the industry to explore how to integrate reusable cable ties into specifications and make them available for purchase in New Zealand retail stores.

Soft plastics and cardboard

Soft plastics and cardboard were the bulk of the materials that were diverted from the general bin by volume. Naylor Love got in touch with Saveboard, a supplier utilising circular economy principles to upcycle packaging (soft plastics and tetra packs) to manufacture low carbon building materials. Naylor Love sends its leftover soft plastics to Saveboard and purchases hoardings from Saveboard. Once they are no longer needed, Naylor Love will be able to send the hoardings back to Saveboard and the hoardings will be remade again into new building materials. This helps creates a fully circular economy product.

PVC

Marley, Naylor Love’s PVC supplier on the project, agreed to take back PVC off-cuts from the worksite so they can be remade into new Marley pipes. Marley has partnered with Waste Management and Unitec on a project to minimise construction waste by breaking down pvc pipe off cuts made of PVC and HDPE and using the material to make new pipes. Previous Naylor Love projects took part in the Plastics Innovation Fund, granted by the Ministry for the Environment. Waste Management arranged the logistics to pick up the leftover PVC from the AUT North Campus worksite.

Sto buckets

Naylor Love worked with STO, a plastering manufacturer, to take back their clean buckets and make the buckets available for customers to reuse when mixing STO’s dry plastering mixture. Sto is now setting up a nation-wide take back scheme to ensure its buckets can be reused multiple times.

Hi-vis vests and branded clothing

Naylor Love partnered with Textile Products to remanufacture used and damaged branded work clothing into a repurposed resource that had a new use on site. An innovative new product called ReTex was created. ReTex is a thick rigid sheet that is used as temporary protection for finished products (for example, for protecting timber balustrades while construction work is still ongoing). Once ReTex reaches the end of its useful life, it will be sent back to Textile Products to be remanufactured and used again.

Plastic drink bottles

Naylor Love wanted to ensure that recyclable plastic products, such as soft drink bottles, were not needlessly thrown into the waste bins. Auckland Council agreed to pick up drink bottles from the AUT North Campus worksite as part of their municipal curb side collection. As part of its induction training, Naylor Love now encourages its staff to refill and reuse their plastic drink bottles.

Timber

In collaboration with its concrete sub-contractor, most of the formwork untreated timber was de-nailed, stacked and sent to the next job to be reused. The Resource Sorters stacked lengths of timber that were longer than their arm to be reused on site.

Polystyrene

The foundations of the new building on the AUT North Campus site were designed to include polystyrene, which acts as a lightweight fill between ground beams. Right from the start of the foundations stage, Naylor Love struggled with the sheer quantity of polystyrene which the sub-contractor ended up over-ordering, approximately 100m3 more polystyrene than was required. Naylor Love partnered with the University of Auckland to research this polystyrene waste. The research found that the polystyrene could be remanufactured, and that the manufacturer could complete shop drawings and manufacture pre-cut shapes to reduce waste on site. As a result, Naylor Love has developed a new operating methodology to bag the polystyrene offcuts and transport them back to the manufacturer.

- Ministry for the Environment – Plastics Innovation Fund(external link) - environment.govt.nz

- Marley – Plastics Innovation Fund(external link) - marley.co.nz

- Sto - sto.co.nz(external link)

- Saveboard(external link) - saveboard.nz

- Textile Products(external link) - textile.co.nz

Outcomes and benefits

Increased waste diversion from landfill

The waste trial has been a great success and Naylor Love is on its way to fulfilling its contract obligations to AUT. By separating resources on site and making changes to how they used specific building products and materials, Naylor Love was able to divert over 90 percent of its construction waste from landfill.

Naylor Love estimates that it saved 71 tonnes from going into the landfill during the trial period. Indeed, so many products and materials were being diverted from landfill that Naylor Love had to downsize their general bin. The general bin was taking over a month to fill and was mainly filled with food scraps. This became a health hazard, so Naylor Love downsized the bin from 9m3 to 4.5m3. The general bin has stayed small even after the waste trial period had finished.

Reducing waste is good for the bottom line

Although the environmental benefits of the waste trial were clear, Naylor Love wanted to understand whether its efforts would also result in commercial benefits. Some in the company were concerned that this new approach would increase time and resources. To test whether that was really the case, Naylor Love involved Michelle, one of their estimators/quantity surveyors, from the very beginning. Michelle’s responsibility was to collect the data and understand the financial implications of the project.

Michelle compared the costs of their standard approach of hiring waste bins from Green Gorilla (a skip provider which practices waste sorting offsite) versus their new approach of using on site Resource Sorters. She calculated the standard approach would usually incur around $40,000 in landfill costs (based on the usage of 9m3 general bins). By using Resource Sorters at the AUT North Campus site, Naylor Love made a saving of 40 percent of its usual landfill costs. Naylor Love also found some indirect commercial benefits as a result of its new environmental approach. Clients were telling them that they were choosing Naylor Love because of its waste management practices.

Improved relationships with stakeholders

The waste trial required Naylor Love to collaborate with a broad range of stakeholders. There were of course the relationships they had with AUT (the client) and Auckland Council (funder and waste advisor). But the task of onsite waste management created a much wider ripple effect on many of the other companies that they worked with.

Naylor Love found there were many opportunities to team up with suppliers to improve environmental outcomes. Suppliers like Marley, Sto, Saveboard and Textile Products were committed to developing circularity into Naylor Love’s supply chain, and logistics providers like Waste Management and Green Gorilla helped facilitate that process. These relationships have continued to grow and some of these companies have been inspired to make bigger sustainability-related changes to their operations.

An upskilled and engaged workforce

Naylor Love employed an external labour-hire company and trained the labourers to become qualified Resource Sorters. During the training process, the Resource Sorters have been encouraged to have a voice and take ownership of their work. As a result, they have ended up making improvements to the resource sorting process over time. Seeing the benefits for their workers, the labour-hire company has been very supportive of the training. Naylor Love has received feedback that the knowledge the workers have gained has been taken into their home environments, increased their mana, changed behaviours, and even led to wider environmental community action.

The micro-credential that Naylor Love created has made a helpful resource for the construction sector. NZQA has assessed the micro-credential to be equivalent to 5 credits at Level 2 on the New Zealand Qualifications Framework. Knowing that everyone on site interacts with building products and materials, Naylor Love made sure to involve all workers on site on the environmental journey. An independent facilitator delivers training to all Naylor Love worksites to uplift everybody’s practices. Naylor Love has also made the course publicly available so that others in the wider sector can improve their waste management practices.

Lessons learned

Little things can make a big difference

Naylor Love’s examination of the building products and materials it was using had a big impact on its ability to reduce construction waste. It found that even the smallest items, like cable ties, can become a big source of waste in large quantities. Many building products and materials that would previously have been sent to landfill found second lives and became part of the circular economy.

There are still barriers to a fully circular economy

Despite its best efforts, Naylor Love found it was still difficult to achieve a fully circular economy in their supply chain. The biggest barrier was the cost and organisation of logistics. While Naylor Love could collect and sort resources on site, it found it difficult to move the used resources to recyclers and upcyclers. Some logistics providers were able to move individual resources (e.g. Waste Management for PVC, Auckland Council for plastic water bottles), but there was no singular provider that was able to collect and transport all excess resources off site.

Other challenges that Naylor Love encountered was a lack of product stewardship from some manufacturers, no end-of-life markets for certain resources, and difficulty in keeping excess building products and materials clean whilst on site (because dirty, dusty, or contaminated goods can be rejected by recyclers and up cyclers).

Winning hearts and minds takes time (and evidence)

When Naylor Love first began its sustainability journey, there were a number of skeptics within the company who doubted that the business could become more eco-friendly and were resistant to change. Environmental champions, like Annie, used tools and research to show that not only was becoming environmentally conscious feasible, but it was also in the company’s best interests.

Those attitudes and concerns about time, resources and cost resurfaced when Naylor Love began the waste trial. To address that, Naylor Love made sure to involve one of their estimator / quantity surveyors from the very beginning. By costing the project from the very start, Michelle was able to show that reducing construction waste was good for business and the bottom line.

Upskilling people is worth the effort

Training people up to become skilled Resource Sorters made a big difference to the outcome of the waste trial. Naylor Love found it was important to spend time finding the right people who were engaged and took ownership of their work, as some people were not a good fit for the role. Naylor Love is now asking for all labourers on their sites to have the Resource Sorters qualification.

Naylor Love made sure that all the workers on site, not just the Resource Sorters, received training on how to sort through, separate and distribute the right materials into the right bins. As a result of the training, Naylor Love was able to achieve its waste diversion objectives. The training helped shift the company’s culture and people’s behaviours to becoming much more environmentally aware.